Industrial lubricants classified as “food grade” are primarily used to maintain food production equipment. Food Grade Lubricants carry out the same technical work as conventional lubricants; they must resist food product deterioration, display chemical behavior that is neutral toward processing machinery and food packaging and adhere to laws governing the health and safety of food.

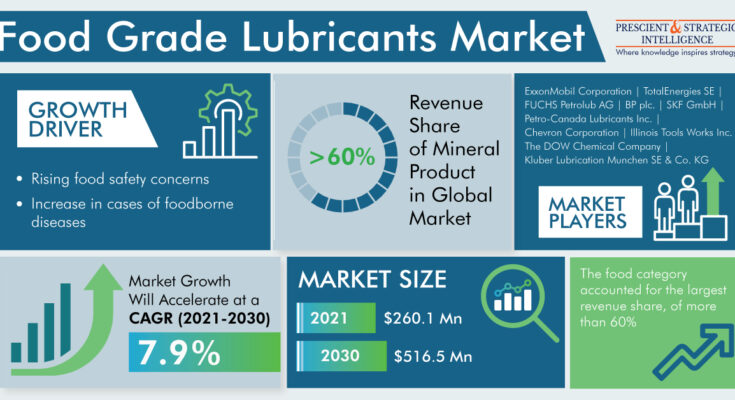

By 2030, it is predicted that the food-grade lubricants market will be worth $516.5 million. This can be attributed to the growing global worries about food safety as well as the rise in occurrences of diseases from unhygienic food.

Get More Insights: Food Grade Lubricants Market Revenue Estimation and Growth Forecast Report

Such diseases are becoming more common; worldwide, each year, 650 million individuals suffer from them, according to the latest statistics. A lot of food-related illnesses are brought on by unintentional contact with the lubricants used in machinery.

Therefore, there is a high demand for food-grade lubricants to prevent contamination of both raw materials and finished goods.

The need for processed canned food products has changed as a consequence of the shifting lifestyles of the population. The consumption of processed food is rising rapidly, especially in emerging economies, due to people’s busy schedules, lack of time to make home-cooked meals, and increasing urbanization. Units that produce processed foods employ lubricants that are suitable to use in food.

Manufacturers Are Shifting Towards Automated Units

The adoption of automatic lubrication systems has significantly increased as a result of recent technological breakthroughs. The deployment of such technologies lowers maintenance costs while reducing equipment failure likelihood by 50%.

Both stationary and moving equipment that can have their lubricant supply controlled at regular intervals can benefit from these systems. They also help to lower the possibility of pollution.

To guarantee that the products they create are of the highest quality, manufacturers are now turning to automated systems, which are generating attractive prospects for the food-grade lubricants demand growth.

Additionally, as customer worries over food safety increase, makers of food-grade lubricants may have additional opportunities to develop and launch new products.

Mineral Category Lead the Segment

The most revenue is produced from the mineral food-grade lubricants category. Their low price in relation to other goods and their strong need in the food, beverage, and cosmetic sectors are credited with this.

Additionally, consumers are increasingly more conscious of mineral oils than synthetic and bio-based oils. Additionally, the existence of more mineral oil manufacturers is crucial to the expansion of the industry in this sector.

Europe Is Dominating Region

Geographically, the Europe industry generated $89.1 million in the past, which is predicted to grow at a CAGR of 8.1% in the coming years. This is because of the matured and well-established industries.

Additionally, the post-recession economic recovery and the rising need for lubricants and grease in contemporary machinery are anticipated to propel food-grade lubricants market expansion.

The growing demand for processed foods and drinks is another important element driving the area’s demand for bio-based food-grade lubricants. The demand for such lubricants in the food processing sector is anticipated to increase as consumers become more aware of the health advantages of processed food.