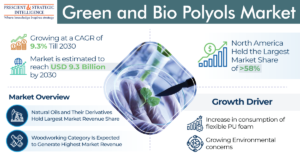

The global green and bio polyols market size is projected to be USD 9.3 billion by 2030, growing at a CAGR of 9.3%, according to P&S Intelligence.

This development can be credited to the growing knowledge of environmental conversation and the government guidelines for lowering the utilization of polyols made from petroleum.

The growing requirement for flexible PU or stiff foams in the construction industry and the woodworking sector is also projected to drive the demand for such chemicals throughout the globe.

Bio-Based Polyols Are in High Demand in Construction, Automotive, and Furniture Industries

Isocyanates, polyols, and several other additives are utilized in the manufacturing of polyurethanes, which are extremely versatile polymers for the woodworking and other sectors. However, the former generation of polyols is low on both quality and performance, thus driving the demand for bio-based alternatives.

Furthermore, bio-based organic compounds are extensively utilized in the automotive sector as they have the potential to advance the hardness of molded foams, which are utilized in vehicle headrests and seats.

Get the sample pages of this report: https://www.psmarketresearch.com/market-analysis/green-bio-polyols-market/report-sample

Worries for Non-Renewable Resource Exhaustion and AQI Degradation

The growing anxieties regarding the deficiency and unsustainability of non-renewable resources and the thinning of the atmosphere from their utilization have led to several steps to encourage the production and usage of bio-based chemicals.

The U.S. EPA and REACH have introduced numerous rules in this regard. Damaging VOCs are utilized as a key ingredient in old-style polyols, while the bio-based alternatives contain zero or tremendously low quantities of such chemicals.

Polyether Polyols Sales Are Most Profitable for Chemical Firms

In 2022, polyether polyols had the largest revenue share, of above 62%, and they are projected to be in the leading position throughout the forecast period.

Such chemicals are widely utilized in the production of soft and rigid foams, flexible PU foam, and molding foam items due to their easy obtainability and better structural integrity.

Polyether polyols have several hydroxyl chains and groups of ether in their molecular arrangement. The new propylene-oxide-based polyether polyol (PPG) has an advanced main hydroxyl range, of around 70%, and shows better reactivity on polyisocyanates.