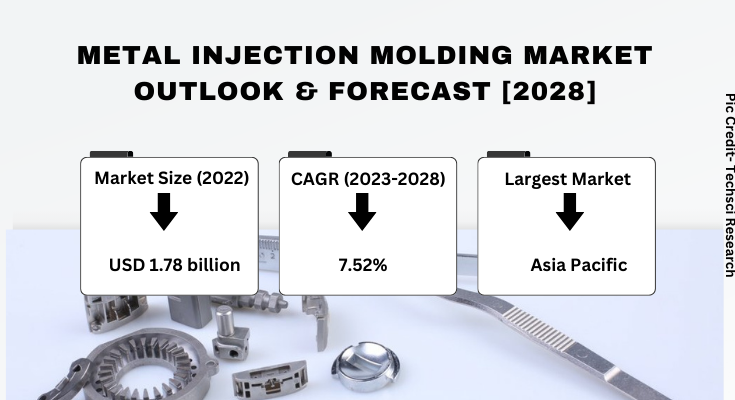

According to TechSci Research report, “Metal Injection Molding Market – Global Industry Size, Share, Trends, Opportunity, and Forecast 2018-2028”, the Global Metal Injection Molding Market is expected to register robust growth during the forecast period owing to a surge in demand in electronics and electrical, healthcare industry driven by technological advancements and the need for lightweight and smaller automotive parts. Also, The Global Metal Injection Molding Market achieved a valuation of USD 1.78 billion in 2022 and is projected to attain USD 3.35 billion by 2028, reflecting a Compound Annual Growth Rate (CAGR) of 7.52% during the forecast period. This market growth is primarily fuelled by the ability of metal injection molding (MIM) to produce high volumes of precision components, making it increasingly popular in the medical sector. The capabilities of MIM contribute to the creation of features for modern medical device products.

In an era where industries demand increasingly compact and intricate components, Metal Injection Molding (MIM) presents a distinctive advantage for manufacturing highly precise parts. MIM excels in producing intricate shapes with narrow tolerances, making it ideal for applications that necessitate miniaturization, such as electronics, medical devices, and aerospace. MIM offers the potential to customize components according to specific customer requirements, empowering manufacturers to penetrate niche markets with tailored solutions. This adaptability caters to industries with unique demands, including luxury goods, precision instruments, and specialized machinery.

Browse over XX market data Figures spread through XX Pages and an in-depth TOC on the “Global Metal Injection Molding Market.” @ https://www.techsciresearch.com/report/global-metal-injection-moulding-market/2251.html

The Global Metal Injection Molding Market is segmented based on material type, end-use industry, and region. Based on material type, the market is bifurcated into wood, ceramic, metal, fiber cement, and others. Based on the end-use industry, the market is bifurcated into residential and non-residential. Based on region, the market is further bifurcated into North America, Asia-Pacific, Europe, South America, Middle East & Africa. Based on material type, the Stainless Steel segment is expected to dominate the market during the forecast period.

Stainless steel MIM components often necessitate meticulous sintering processes to attain the desired mechanical properties while upholding corrosion resistance. Certain stainless steel alloys may incur higher costs, impacting overall component expenses.

Advancements in MIM technology are facilitating the production of intricate stainless steel components with precise geometries and enhanced mechanical properties. The recyclability of stainless steel is renowned, contributing to sustainable practices in the MIM industry. The Stainless Steel segment within the Global Metal Injection Molding Market is anticipated to witness growth as industries continue to seek components that offer a blend of mechanical strength, corrosion resistance, and aesthetic appeal.

Based on the end-use industry, the Electrical & Electronics segment is projected to dominate the market throughout the forecast period. The demand for MIM components in the Electrical & Electronics sector is fueled by the necessity for miniaturization, enhanced performance, and increased functionality of electronic devices and systems. The remarkable ability of MIM to manufacture intricate and small parts with exceptional dimensional accuracy perfectly aligns with the industry’s requirements. MIM is extensively employed in the production of small connectors, pins, and contacts with intricate shapes and precise dimensions.

These MIM components find applications in switches, sensors, and actuator mechanisms, which are integral to various electronic devices. Furthermore, MIM plays a vital role in manufacturing components for microelectronic packaging, ensuring efficient heat dissipation and reliable electrical connections. The selection of materials in the Electrical & Electronics sector is based on their conductivity, thermal properties, and compatibility with electronic systems. As technology continues to advance, propelling the demand for compact, efficient, and high-performance components, the Electrical & Electronics segment within the Global Metal Injection Molding Market is anticipated to experience significant growth.0

Key market players in the Global Metal Injection Molding Market are:-

- Tata Steel Ltd

- Compagnie de Saint Gobain SA

- Etex Group

- Kingspan Group

- James Hardie Industries PLC

- Boral Limited

- CSR Building Products

- Nichiha Corporation

- Cembrit Holding AS

- OmniMax International, Inc.

To Download FREE Sample Pages of this Report📥 @ https://www.techsciresearch.com/sample-report.aspx?cid=2251

Customers can also request for 10% free customization on this report.

“Asia Pacific is expected to dominate the market during the forecast period. Asia Pacific’s renowned reputation for efficient and cost-effective manufacturing serves as a prominent catalyst for the growth of the MIM market. The region’s expertise in high-volume production of intricate components aligns seamlessly with the capabilities of MIM technology. Moreover, the increasing healthcare expenditures and demand for medical devices in Asia Pacific present significant opportunities for MIM in the production of components for surgical instruments, orthopedics, dental tools, and other applications. Notably, MIM technology’s remarkable ability to manufacture complex shapes and intricate geometries complements the region’s ongoing trend towards miniaturization in electronics and precision engineering.” said Mr. Karan Chechi, Research Director with TechSci Research, a research-based global management consulting firm.

“Metal Injection Molding Market – Global Industry Size, Share, Trends, Opportunity, and Forecast, 2018-2028, Segmented By Material Type (Stainless Steel, Low Alloy Steel and Soft Magnetic Material), By End-use Industry (Automotive, Medical & Healthcare, Electrical & Electronics and Others), By Region, Competition,” has evaluated the future growth potential of Global Metal Injection Molding Market and provides statistics & information on market size, structure, and future market growth. The report intends to provide cutting-edge market intelligence and help decision-makers take sound investment decisions. Besides the report also identifies and analyzes the emerging trends along with essential drivers, challenges, and opportunities in Global Metal Injection Molding Market.

You may also read:

Distemper Market [2028] – Analysis, Trends, & Insights

Road Haulage Market | [2028] Exploring Potential, Growth, Future & Trends

Underwater Concrete Market | [2028] Exploring Market Growth, Potential, Trends

Table of Content-Metal Injection Molding Market

- Product Overview

1.1. Market Definition

1.2. Scope of the Market

1.2.1. Markets Covered

1.2.2. Years Considered for Study

1.2.3. Key Market Segmentations

- Research Methodology

2.1. Baseline Methodology

2.2. Key Industry Partners

2.3. Major Association and Secondary Sources

2.4. Forecasting Methodology

2.5. Data Triangulation & Validation

2.6. Assumptions and Limitations

- Executive Summary

- Impact of COVID-19 on Global Metal Injection Molding Market

- Voice of Customer

- Global Metal Injection Molding Market Overview

- Global Metal Injection Molding Market Outlook

7.1. Market Size & Forecast

7.1.1. By Value

7.2. Market Share & Forecast

7.2.1. By Material Type (Stainless Steel, Low Alloy Steel and Soft Magnetic Material)

7.2.2. By End-use Industry (Automotive, Medical & Healthcare, Electrical & Electronics and Others)

7.2.3. By Region (North America, Europe, South America, Middle East & Africa, Asia Pacific)

7.3. By Company (2022)

7.4. Market Map