If you are still using the old refrigerators or HVAC system, then it is quite obvious that you should think of an upgradation of your air compressor. We are living in the age of advancement, then switching from a legacy air compressor to an inverter air compressor can really be a good idea on your part. Conventional air compressor consumes a lot of energy and have only a handful of settings regarding temperature.

On the other hand, an inverter air compressor is controlled by digital signals. These use variable-speed motors for giving more temperature adjustments and consumption of energy. This blog will provide you some information about why you should also upgrade to the inverter air compressors.

They Have Higher Output Capacity

Inverter air compressors can give more output than their traditional counterparts. Variable-speed motors is the main component responsible for improved output. With adjustable speeds, it spins faster for compressing warm air from the refrigerator or a warm room. The motor can also function at low velocity, saving a lot of energy throughout off-peak periods.

These motors receive a signal from sensors within the compressor. Consequently, they have higher capacity by volume. Inverter systems don’t fluctuate with their output.

They Operate Rather Quietly

Inverter air compressors don’t make any noise. These use adjustable speeds and direct current for reducing noise. Consequently, there will be no irritating sounds entering into your ears.

Inverter converts AC into DC in the modern systems. DC then combines with a magnetic field for operating a variable motor. The use of magnets helps you with a quieter operation in commercial and residential applications.

They are Energy Efficient

Conventional air compressors can consume a lot of power if there is overheating. Legacy Conventional compressors becomes since the motor functions on an on/ off mechanism. This is the reason; they consume more energy and have to be regularly maintained. The inverter ones are rather energy efficient than their traditional counterparts.

They Have Precise Temperature Adjustments

Precise temperature control is the need of the hour, if you are to store perishables. Traditional compressors need a specific change in temperature to switch it on and off. inverter compressors are more sensitive to changes of temperature. These compressors are responsive to digital signals, the temperature settings can be altered according to the application.

Fluctuations in room temperature are also well taken care of by inverter compressors. This is the reason, why it is a good option for residential as well as commercial climate control. After upgradation, there is no need to worry about maintaining a consistent temperature.

They Have Low Torque and Modern Design

A high startup torque is required by conventional air compressors as they have electromagnetic coils. This drains energy and causes deterioration of moving parts. Inverter air compressors functions through a magnetic system. It is due to the fact that magnet can power units even at low speeds, there is no need of torque for starting the cooling process.

The contemporary design of the inverters also makes the installation and retrofitting into the buildings easy.

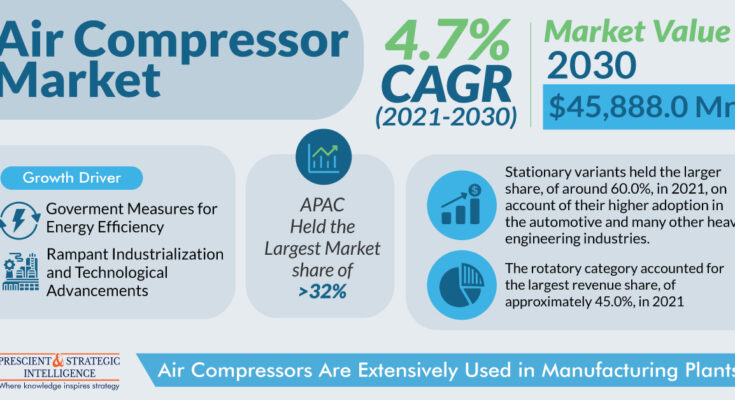

With rapid industrialization and technological advancements, the demand for air compressors is on the roll, and will reach a value of $45,888 million by 2030.