Industry 4.0 to Bring Transformation to Industrial Robotics

Industry 4.0, the new era, is distinguished by the speed of technological advancements. It requires employing advanced robotics to boost efficiency. The growing requirement for automation and rise in investments in R&D activities drives the growth of the global industrial robotics market. According to Allied Market Research, the global industrial robotics market is anticipated to grow at a significant CAGR from 2021 to 2030.

To meet the growing demand for industrial automation and robotics, market players are relying on two key strategies: new product launches and collaborations. An industrial automation firm, Veo Robotics, recently announced a strategic partnership with a leading automation services supplier for the food and beverage industry, Gray Solutions. This collaboration enables Gray Solutions to include the safety-certified flagship product of Veo in collaborative palletizing solutions for the CPG market. The association comes at a time when CPG manufacturers and warehouse distributors are ramping up automation to solve labor shortages and supply chain restrictions while preserving productivity.

Food and consumer goods industries employ robots to stack products on pallets for delivery and are among the fastest-growing areas for robot orders. However, even low-risk, high-automation operations like robotic palletizing require humans to interact with a robot. Veo’s FreeMove enables 3D speed and separation monitoring, allowing robots to safely and efficiently work alongside human teammates. Additionally, FreeMove can enable human-robot collaboration using industrial robots instead of Power and Force Limited (PFL) robots, thus allowing CPG production engineers to compromise speed, reach, or payloads. Veo’s FreeMove technology holds the potential to unlock the literal value of human-robot collaboration.

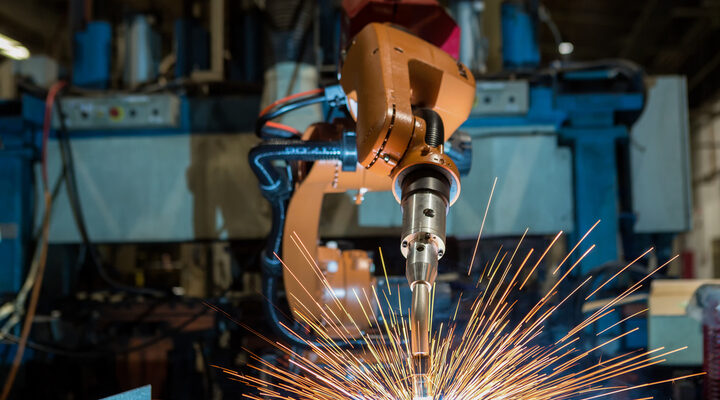

The industrial manufacturing process is one of the primary sectors where robots have a lot of potential and demands. Even after the evolution of industrial robotics, the assembly and inspection processes of a high-mix and low-volume production (HMLV) are harmful to humans and remain a serious concern. Automating these manufacturing processes necessitates frequent changeovers and usually takes multiple generations of advancements to achieve excellent performance and dependability. This is making industrial automation and robotics challenging and complex.

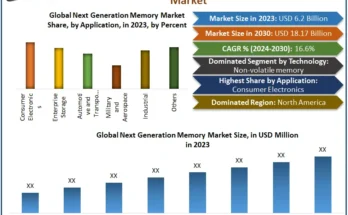

The demand for industrial robotics is expected to continue to rise as the labor shortages in the manufacturing industries are worsening with time. Along with the growth for robot hardware, software intelligence is anticipated to increase, making robots more flexible to new applications and allowing less experienced users to manage them more effectively. Advanced technology, including machine learning, AI, and motion planning, is anticipated to build a next-generation manufacturing business.

Leading players are investing in continual product innovation and new launches to address industrial concerns. ABB is expanding its portfolio of robots for challenging manufacturing applications by adding two new robot models: IRB 5710 and 5720. These robots deliver increased efficiency and enhanced functionality with higher uptime for applications such as electric vehicle (EV) production, foundry, rubber, forging, plastics, and metal fabrication. These models also offer improved speed, flexibility, accuracy, and an enhanced robust design that includes integrated process cabling.

Growing advancements in industrial robotics are expected to aid the industry in addressing the critical robotics and automation challenges. This will further improve the market demand and accelerate the 4th industrial revolution.